Chances are that if you’re reading this, you’re interested in procuring goods for your business.

If you want to obtain goods from suppliers in a smooth, predictable and organized fashion, using purchase orders can certainly help.

In this article, you’ll learn:

- What is a purchase order?

- What a purchase order is used for

- How purchase orders work

- How to create a purchase order

- What a purchase order number is

- The difference between a purchase order and an invoice

- The 4 different types of purchase orders

- How to manage purchase orders

- How to create a purchase order in Lightspeed

Let’s dive in!

You’re in luck! Download our free purchase order template to help standardize your ordering process, ensure accurate record-keeping and save time.Need a purchase order template?

What is a purchase order?

A purchase order (PO) is an official document that’s issued by a vendor to pay a supplier for the sale of a list of specific products or services that will be delivered in the future.

Typically, a PO includes the types, quantities and prices of the products or services being purchased by the vendor. The more specific an order is and the more details a vendor includes, the more effective the PO will be.

Once a supplier accepts a vendor PO, it forms a legally binding contract between the vendor and the supplier. That’s why it’s important for vendors to include as much pertinent information as possible in their POs.

Purchase orders are incredibly useful for controlling and documenting the purchase of products and services from external suppliers.

What is a purchase order number?

Each PO has a unique purchase order number associated with it that helps both vendors and suppliers track delivery and payment.

What is a purchase order used for?

One of the key benefits of purchase orders for vendors is that they can place an order without needing to immediately pay for the order. For suppliers, a PO is a way to give vendors credit without any risk, since the vendor needs to pay once the products or services are delivered.

What are the benefits of purchase orders?

Along with the cash flow benefits, there are a few other reasons why POs are so beneficial for vendors and suppliers alike:

- Greater accuracy for inventory and financial management.

- Improved budgeting because funds need to be available prior to a PO being issued.

- Quicker delivery, since POs help a vendor schedule deliveries for when they need it.

What are the cons to purchase orders?

We can go on record and say that POs have a lot more pros than cons. As far as cons go, there are a couple:

- More paperwork for smaller purchases.

- From a strictly financial perspective, using a credit card can serve the same purpose.

But if you want to keep your financials and inventory management organized and accurate, purchase orders are the way to go.

How does a purchase order work?

A PO is meant to simplify the purchasing process between vendors and suppliers. While each retailer’s process can differ, here’s an example of how a typical purchase order process looks:

- The vendor decides to purchase a product for their business.

- The vendor issues a PO to the supplier, oftentimes electronically using a purchase order template.

- The supplier receives the PO and confirms to the vendor that they can fulfill the order. If not, the supplier lets the vendor know and the PO is canceled.

- If the supplier can fill the order, they start preparing the order by pulling the requested inventory and scheduling personnel to package and ship the order.

- The order is shipped to the vendor’s specified delivery location with the PO number on the packaging list.

- The supplier invoices the vendor for the order using the PO number so that it can be quickly matched with the shipment’s delivery information.

- The vendor pays the supplier according to the invoice terms specified in the PO.

How to create a purchase order

While each business is different, most POs will include:

- Company and vendor name

- The quantity being purchased

- The product or service being purchased

- Brand names, SKUs or model numbers

- The price per unit

- Delivery date

- Delivery location

- Billing address

- Payment terms (such as payment upon delivery or within 30 days after the vendor receives the order)

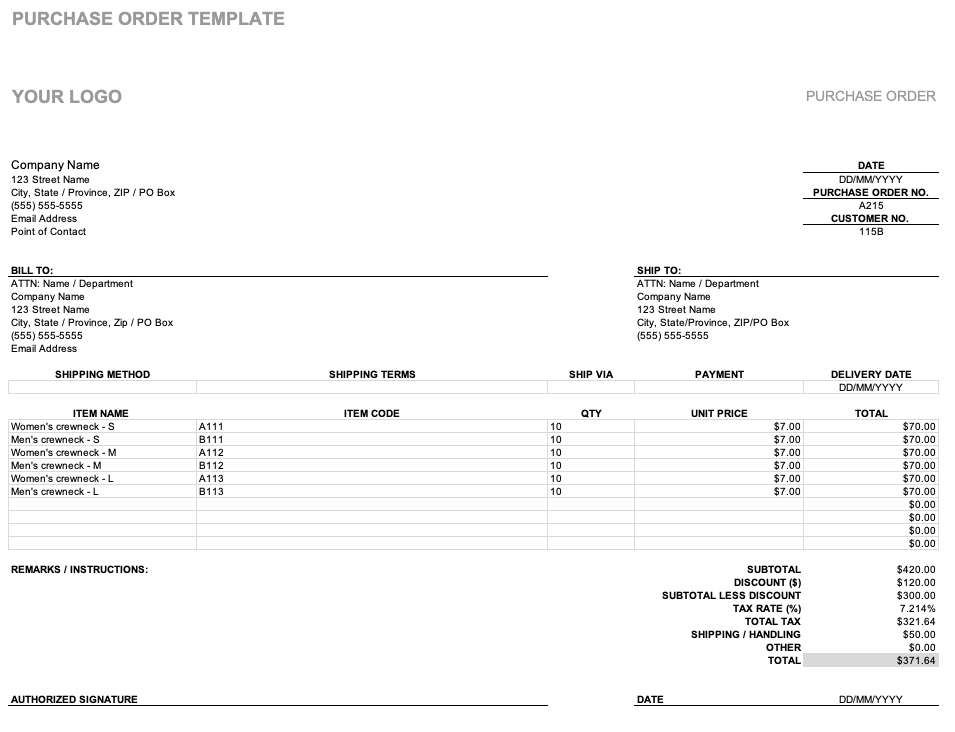

What does a purchase order look like?

Purchase orders are typically a standardized document that contains company information (name), shipping details (delivery and billing address), supplier information (name and address) and order information (product, price, quantity, delivery date and payment terms).

Many retailers opt for standardized purchase orders to maintain consistency between them and their suppliers.

This is what a purchase order looks like, courtesy of Lightspeed’s free downloadable purchase order template.

How to create a purchase order in Lightspeed’s Retail POS system

Lightspeed Retail POS has robust inventory management capabilities to make merchants’ lives easier.

Merchants can create and send purchase orders to vendors in one place, with no clunky Excel spreadsheets necessary.

If you’re interested in seeing how to batch import items into a purchase order, set automated reorder points or build special orders, check out our Help Center article on creating purchase orders for a step-by-step walkthrough.

What’s the difference between a purchase order number and an invoice?

The main difference between a PO and an invoice is who creates the document. A vendor creates a PO, which needs to be fulfilled by the supplier. A supplier prepares an invoice for the order and issues it to the vendor.

For example: Let’s say a clothing store is running low on t-shirts. The retailer (vendor) prepares a PO that lists exactly what types of t-shirts they want (size, color, quantity, price, SKU number) as well their desired delivery date, delivery location and billing address.

If the supplier can fulfill the PO, they will accept the order, which forms a legally binding contract between the vendor and supplier. Once the vendor receives the goods they ordered, they initiate a payment to the supplier for having provided the products or services specified in the PO.

So, in a nutshell, a PO is for a vendor to order products, whereas an invoice is for a supplier to get paid by the vendor for supplying the products.

The 4 types of purchase orders

While you may think that all purchase orders are the same, that’s not the case. There are actually four types of purchase orders that a retailer can use, each with their own use cases and benefits.

1. Standard purchase orders

Just like the name suggests, standard POs are the most commonly used. In a standard PO, the vendor specifies:

- What items they’re buying

- The quantity of each item they’re buying

- The delivery location and date

- Payment terms

2. Planned purchase orders

When a vendor places a planned purchase order, they anticipating their future needs for an item and submitting a PO in advance. In a planned purchase order, the vendor specifies:

- What items they’re buying

- The cost of those items

- The delivery location

- Payment terms

For planned purchase orders, the quantity of items is based on an estimation and delivery dates are tentative, usually within a set timeframe (for example, anytime between November 1 – 15).

3. Blanket purchase orders

A blanket PO is a commitment from a vendor to buy products or services from a supplier on an ongoing basis until a specified order value is reached. Usually, the vendor places multiple orders at the same time to benefit from preferential pricing.

4. Contract purchase orders

With a contract PO, both the vendor and supplier sign a contract that specifies the terms of the purchase before a purchase order related to the contract is issued. While the penalties for breaching a contract purchase order vary, both the supplier and vendor have the ability to take legal action should the other party not fulfill their end of the contract.

The main benefit of contract POs is that they offer more legal protection for both vendors and suppliers. Typically, we see contract purchase orders for large orders where vendors want legal backing should a supplier make errors, or suppliers want assurance that the vendor will pay them in a timely fashion.

How to manage purchase orders

While POs can be relatively straightforward, they can still add complexity to your supply chain process if you’re not accustomed to using them. For retailers, it’s important to invest in solid inventory management software and find a process to manage suppliers that works for you.

Here are a few tips for managing purchase orders:

1. Use technology to streamline inventory management

The best thing you can do for managing purchase orders is investing in a retail point of sale system with great inventory management capabilities. Lightspeed Retail POS has integrated vendor catalogs and merchants can create and send POs within the system. Best of all? Everything is documented and stored on the cloud, so you never lose important information.

2. Order in bulk to lower costs (if you can)

By ordering items in bulk, vendors can benefit from preferential item pricing and a lower cost per unit. Of course, by ordering in bulk you’re spending more upfront, so you should only explore this option if your business is stable and you’re confident you can sell the merchandise.

3. Be timely to foster great relationships with suppliers

Always send your purchase orders, invoices and contracts in a timely manner. Not only will that assure that you have a predictable, steady flow of the inventory you need, but suppliers will appreciate your professionalism, have confidence in your ability to pay them and want to continue working with you.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.