As a retailer, doing physical counts of inventory probably isn’t on your list of favorite things to do. A tedious task, taking count of store merchandise can take hours. For some merchants, it also requires closing the store temporarily.

But even if it’s a job you’re not too fond of, taking a physical count of inventory is a must for any retailer. Keeping a close eye on the stock you have on paper vs. what’s actually in your store helps you maintain inventory accuracy, spot causes of shrinkage early, and ensure that you always have the right amount of stock at the right time.

In this post, you will learn:

- What is a physical inventory count?

- 10 stock counting tips for retailers

- What to do after counting

- Addressing discrepancies

Don’t get stuck with inefficient inventory practices. With our easy-to-use inventory spreadsheet template, all you have to do is enter your data and watch it calculate for you.Streamline inventory management in your retail business

What is a physical inventory count?

A physical inventory count is the practice of counting your retail products in person. The process typically involves a retail staff member (or team of workers) going through the retailer’s sales floor and stock room and counting each item. The data is then recorded either manually, using pen and paper or electronically using a mobile device.

The objective of a physical inventory count is to audit a store’s inventory and ensure that the stock data the retailer has on paper matches the inventory that’s actually in the store.

To help make this task easier on you, we’ve compiled a few practical pointers on establishing your physical inventory count process, conducting stock counts, and more. Check them out below.

10 Stock Counting Tips for Retailers

Now that we’ve covered the fundamentals of physical inventory counts, here are some actionable tips to make inventory counts much more efficient in your business.

1. Taking a physical count of inventory? Consider cycle counting

Have you ever tried cycle counting (aka partial stock-takes)? It’s the process of partially counting merchandise on a continuous basis, helping you monitor stock levels without interrupting store hours. Cycle counting can be done daily or weekly (usually before the store opens) and can free you from having to do full inventory counts. That’s why it’s one of the most efficient inventory counting methods for retailers.

Philip Pravda of SuitCafe.com highly recommends this method. “I owned four luxury menswear shops, and my method for taking physical inventory was almost daily,” he shares.

“I would choose small sections of the store, or a particular brand of shirt, suit, coat, etc. I would count them up with the style numbers and sizes. Then walk over to my computer and compare. Doing the whole store for a small business is difficult because you are always helping customers and certainly do not want to close early or for a full day to do inventory.”

Similarly, Preston Wily of the ecommerce site SewellDirect.com says that conducting partial inventory counts has worked well for them.

“Our shipping department employees are each assigned a handful of audits to do every week–high volume products come up for audit much more frequently than low-volume sellers, but each product is counted at least once per year,” he says. “We also catch problems a lot sooner, which keeps them from becoming huge issues.”

On the other hand, if cycle counting isn’t your cup of tea, or if you feel that you have to do a full inventory count in addition to partial stock takes (as some retailers do), the other tips in this post should make your life easier.

2. Use inventory scanners or other types of stock counting technologies

Traditionally, physical inventory counts are done with a pen and paper. The staff would use a physical inventory count sheet to tally up the products and reconcile the data in their system.

While this method can get the job done, it’s highly inefficient, and it requires double entry. Not to mention, since physically counting inventory is already a “manual” task as it is, the last thing you need is to tally and record data by hand.

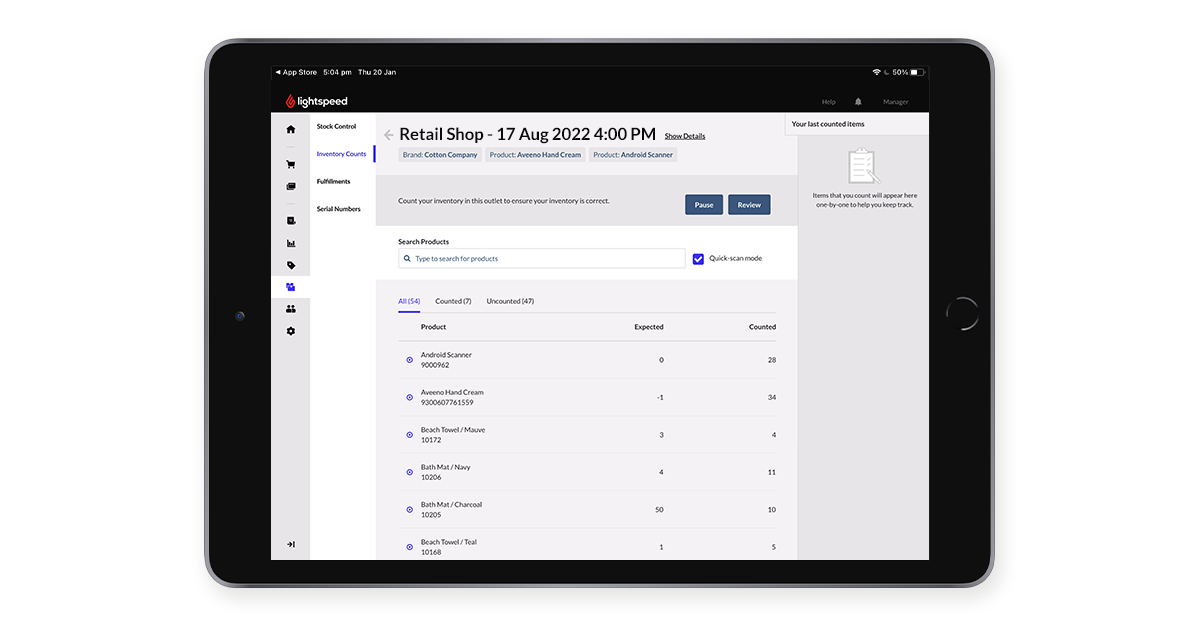

If you’re using a POS or inventory management software, check to see if it has built-in inventory counting features you can use.

Lightspeed’s Inventory Counts capability, for example, enables retailers to take count of their stock as painlessly as possible. Features like simultaneous stocktakes allow the use of multiple devices to count stock faster, and Lightspeed’s quick scan mode function enables retailers to count inventory by using their barcode scanner or by looking up SKUs.

If you’re already using Lightspeed, check out our stock taking features and take advantage of them the next time you’re conducting physical inventory counts in your stores.

Other technologies you should consider are:

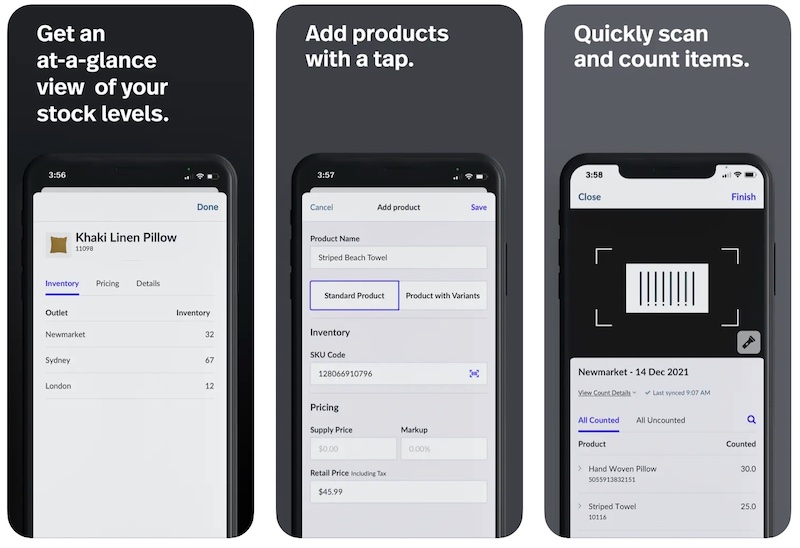

Lightspeed Scanner (X) [IOS | Android] – Digitize the counting process with Lightspeed Scanner (X), a free mobile app that makes counting inventory a breeze.

It lets you do full and partial inventory counts using your iPhone, iPad, or iPod Touch. Just scan your product barcodes using your device’s camera, and the app will automatically save and record all the necessary product information.

Lightspeed Scanner (X) also syncs completed counts with your Lightspeed account, so once you’re done counting, you can easily update your stock levels.

Not a Lightspeed user? The app will create a CSV file that you can easily email to you and your staff.

RFID – Need a more sophisticated tool for inventory counts? Consider RFID technology. Short for Radio Frequency Identification, RFID lets you embed chips into the packaging of your merchandise so you can easily track their location. RFID is really handy, not just from a loss prevention perspective, but also when it comes to maintaining inventory accuracy.

Consider what Mammoth, a sporting goods store in California, does to streamline inventory counts. Instead of doing full inventory counts, the company physically counts its high-ticket, high-shrink items daily and then cycle counts through a percentage of its stock with the goal of counting all its merchandise every two weeks.

Mammoth also uses Truecount RFID software to generate reports of what they have should have on in stock.

“Truecount lets us create a comparison report based on what our computerized inventory system says we have in stock and what we can count,” Mammoth co-owner Phil Hertzog told the NRF. This task is performed after closing, and they reconcile their inventory the following morning to look for discrepancies. If there are any differences, the staff is informed where the missing items should be so the location can be physically checked.

Pro tip: No matter what your tech stack looks like, see that your hardware and software are working perfectly before the count. Check your barcode scanners, review your software’s functionalities, and do some test counts to ensure that everything is ready before the official count.

3. Choose your “counters” wisely

Don’t assign your inventory counts to just any employee. The group conducting your stock counts should consist of seasoned employees as well as those who can provide fresh eyes.

You’ll need seasoned team members, as these employees would be more familiar with your policies and the location of different items. However, someone who’s so used to your store or stockroom may overlook small issues and details, so having people who are a bit new to the team may be beneficial.

Another option is to hire third-party inventory counters. This is helpful if you don’t have the in-house expertise or resources for conducting the count yourself. Now, the actual counting procedure will vary from one provider to the next. It’s best to consult your third-party stock counter and follow their processes.

4. If you must do a full physical inventory count, schedule it ahead of time

The timing of your inventory counting process matters a great deal, so have a think about when (and what time) to schedule your counts, and then plan (way) ahead.

When is a physical inventory usually taken?

The question of when (and how often) you should conduct full physical inventory counts really depends on you. Some stores do it once a year, others conduct it bi-annually, while other stores do it more often.

The Retail Doctor, Bob Phibbs, writes on his blog that it’s best to do it on the last weekend of January or at the end of July because your SKUs are potentially at their lowest during these periods.

Whatever you decide, though, you’ll want to settle on a date well in advance (weeks or even months before) and make sure your employees know what’s coming up. At this stage, you need to take down the names of the people who’ll be helping you with your physical inventory count. Make sure they can make themselves available on the decided date.

Ideally, you wouldn’t want to halt store operations, so if you can manage it, schedule your inventory count after business hours. If this isn’t possible, and you’ll need to close up shop for a day or several hours, be sure to give your customers a heads up.

Alert regulars that you’ll be closed on a certain date, verbally inform people when they’re in your shop, and display a sign outside your store or at the checkout counter detailing the date and times you’ll be closed and why.

5. Communicate, communicate, communicate

We’ve alluded to this earlier, but it’s worth emphasizing: if you’re doing a full inventory count, you must communicate your plans to the right people ahead of time.

Touch base with your team and let them know in advance when you plan to conduct the count and in which locations so they can prepare the products and minimize stock movements on the day that the count occurs.

This could mean scheduling stock deliveries at a different time and pausing in-store trading.

Whatever the case, regular messages and reminders will pave the way for a smooth stock-taking experience.

6. Map your store

Draw up a map of your store and stock room that illustrates where your products are located. As Phibbs notes, you should “Sketch out the location of every rack, display, wall, and shelf if necessary.”

Doing so will give an at-a-glance view of your store and make it easier for you to assign people to each section and determine the best way to go about the counting process (i.e. where to start counting, how to move around the store).

Your map can also serve as a handy checklist when you’re counting products. You can mark off the sections that have already been counted, making it easier to see how much you’ve completed.

7. Label boxes and shelves

Don’t go into the task blind. If you’re doing a physical count of your inventory, mark the boxes or shelves in your stockroom if the products in them aren’t visible.

As the blog Supply Chain Cowboy puts it, “When the time comes to count inventory, having everything in a marked location is a necessity. Those loose boxes and stray pallets without a home are often the problems that come back to haunt you while you try to reconcile. Even if you must make new, temporary locations for the duration of the count, put everything in a well-marked and defined place, and leave it there.”

While you’re at it, make sure everything is where it should be. Walk around the store or stockroom and keep an eye out for items that aren’t in their proper place. Are there tank tops lurking in the footwear section? Did someone mislabel a box of merchandise? Be sure to correct these issues before you begin counting.

8. Think about items that are in limbo

When planning your inventory counts, figure out how you’re going to deal with items in limbo. This could include merchandise in transit—such as outstanding orders from suppliers or products that have been returned. Ideally, these items should be processed and dealt with before performing the count to avoid any confusion later on.

If you’re implementing in-store fulfillment services such as BOPIS and curbside pickup, clearly label items that are pending fulfillment or pickup so you can ensure not to include them when counting.

Ditto for faulty products. If you encounter damaged items before the count occurs, deal with them early on.

9. Orient your staff

See to it that your team is familiar with the steps you took above. If you created a map, show it to them and ensure they know where people are assigned.

Did you change the position of certain items or re-labeled boxes and sections? Tell them—or better yet, show them. Take a walk with them on the sales floor or stock room so they can familiarize themselves with everything. This will make the task of counting and reconciling much easier.

10. Prepare food and drinks for your staff

Water, sodas, and a few boxes of pizza will go a long way in keeping your employees happy and efficient. Physically counting inventory is a tedious process, so you want your team to stay at the top of their game. Keeping them well-fed and watered helps them do just that.

What to do after physically counting your products

Finished counting your stock? Take immediate steps to improve your inventory accuracy. Here’s how:

Double-check and audit your counts ASAP

It’s always a good idea to double-check your inventory numbers before updating your stock levels to ensure everything was counted correctly. And the time to do this is right after you complete your inventory count. The information needs to be fresh in your mind, so avoid postponing your inventory checks and audits.

Pull up inventory reports

Doing so will enable you to analyze the data and see what you can do to improve your business.

This task should be straightforward if your POS or retail management system has reporting and retail analytics capabilities. Just generate the right reports and study the data for actionable insights. Alternatively, you can use a tool like our free inventory spreadsheet to gain the data and insights you need.

Pinpoint high-risk zones

Use your inventory reports to identify high-risk zones or regions in your stores. Tell your staff about these high-risk areas and figure out how you can minimize losses in those regions.

Compare multiple completed inventory count reports

Once you’ve completed multiple counts over a period of time, it’s beneficial to examine those reports so you can spot patterns. This will help you figure out why losses or discrepancies are taking place so that you can take preventive action for the future.

Comparing past reports with current ones will also help you see if your inventory practices are working. Are discrepancies decreasing over time or not? Whatever the case, the only to find out is to compare the data.

Addressing discrepancies

If you encounter discrepancies, take immediate action to get to the root of the issues. Discrepancies can often be traced back to human error, bad math, or missing paperwork. In such cases, you’ll need to tighten up your processes. Document your procedures and automate various steps to minimize mistakes. For instance, if you’re manually entering products into your system, use a barcode scanner or CSV file instead.

Sometimes, inventory discrepancies are caused by more sinister reasons. You could be dealing with theft or fraud in your store, in which case you’ll have to investigate and take steps to prevent and stop the issues.

Whatever the case, the only way to determine what you’re dealing with is to conduct inventory counts regularly, so make it a point to stay on top of this task. Keeping track of your inventory data (ideally using retail reporting software) also helps a ton.

Bottom line

Whether you’re handling inventory management using Excel or are using a retail solution like Lightspeed, stock-taking is a critical part of a running a retail store.

Smooth and painless stocktakes don’t happen by accident. Details are planned well in advance and the products, materials, and tools you’ll be using are prepared beforehand. If you intend to do physical inventory counts anytime soon, be sure to complete the tasks we talked about above. Doing so will make your life so much easier.

Want to learn how Lightspeed can make your inventory counts easier? Watch a free demo to see it in action!

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.