Ah, organization.

Whether you love to check boxes and make lists, or organizing things is the bane of your existence, one thing is for certain: an unorganized inventory is like a lead weight on your retail business. Love it or hate it, you need to keep on top of your inventory management to run your business optimally and—crucially—to make more money.

We’re inventory management pros here at Lightspeed. It’s why we built our retail POS system with robust ordering and organizational tools you can take advantage of to make your inventory work for you. And it’s why we’re excited to share some of our knowledge with you so you can get your inventory in order without stress.

In this post, we’ll go over:

- What inventory management means

- Why inventory management is important

- Inventory management techniques you should know

- Tips for an optimized POS inventory system setup

- Examples of inventory management for different retail verticals

- How your new inventory management skills will help you manage purchasing

- The future of inventory management

Need a hand managing your inventory?

Download our free inventory spreadsheet template to help you better manage your inventory, purchases and sales.

What is inventory management?

Inventory management is every step involved in ordering, organizing, storing and selling inventory.

You know what your inventory is: it’s the products you stock to sell to your customers. And you know inventory management is keeping that stock in order.

But inventory management is much more than just good organization. It also helps you manage the ordering, storage and carrying costs of your inventory, so you get a better ROI from your stock.

Airtight inventory management gives you the information you need to:

- Increase your profit margins

- Decrease excess stock

- Cut down on your inventory costs

- Work in a better, more efficient way

Effective inventory management processes can also help you answer these questions:

- How much of each item is in stock?

- What and when do you need to reorder?

- Are you ordering too much or too little inventory?

- What are your best and worst selling items?

- Should you stop selling something completely?

- Is your inventory storage sufficient?

This information can help you with everything from your next stock order to planning your spring promotional campaign.

Efficient inventory management is a cornerstone of any successful wholesale and retail relationship. Inventory Management Systems (IMS) are vital, monitoring inventory quantity, location and status, as well as associated shipping details. These systems automate and streamline inventory processes, reducing human error and enhancing efficiency.

Warehouse management vs. inventory management: what’s the difference?

If you’re a retailer who operates a warehouse, you’re going to need to approach your warehouse inventory differently than you do your in-store inventory.

Your in-store inventory exists to be sold. When you’re managing it, you’re looking to set it up in such a way that you can examine sales data and see what your customers are responding to and what they aren’t.

Warehouse management is about tracking and controlling the storage of inventory in a warehouse, and while there are some overlapping functions with inventory management, they’re just different enough to require separate systems. Your warehouse inventory exists to be sent to stores (or to be mailed to eCom customers)and must be set up and managed in a way where you can track exactly where it is at all times.

If you’re operating a warehouse, you can make your life easier and use a warehouse management system to integrate your warehouse with your POS. While you’ll still need to keep the different needs of each kind of inventory in mind, integration means less potential for human error in the numbers and details.

What are the four common types of retail inventory?

Not all inventory is the same. Inventory can be classified as raw materials, work in progress, finished goods and maintenance and repairs. Depending on if you primarily resell products, produce your own or offer customers a mix of both, you might have a mix of the following inventory types you’ll need to account for.

Raw materials

Raw materials are just that: raw materials. If you’re at all involved in the production of your inventory, you’ll likely have some of this on hand. Not all retailers will deal with raw materials, however.

If you have raw materials in your inventory, you’ll want to keep them separate from your finished goods’ inventory hierarchy. Goods that might be considered raw materials—lumber, for example—that you have in stock because you intend to sell them to customers are technically finished goods.

Work in progress

Like raw materials, you might have work in progress inventory on hand if you’re involved in the production of the goods you sell. If you do deal with work in progress inventory, your goal should be to ensure items don’t stay at this stage for long.

These items should also be kept separate from your finished goods’ inventory hierarchy. They’re not for sale to customers. If you have inventory in your store that you’re working to update, repair or tune up for customers, that should be classified separately from work in progress goods.

Finished goods

Finished goods are anything you have for sale in your brick and mortar store or on your eCom site. These may be goods you’ve been involved in the production for or goods you’ve ordered from a vendor.

This is the inventory that you’ll be focusing on for your retail inventory management plan.

Maintenance and repair

Say you’re a bike retailer. In addition to selling bikes and bicycle parts, you repair and upgrade bikes for your customers.

The inventory involved here isn’t the bikes themselves, though you will need a clearly defined workflow for handling and storing them to keep your customers’ goods from being damaged. It’s the tools and labor needed to work on the bikes your customers bring you.

Why is inventory management important?

Good inventory management helps you…

Maximize profits

Let’s cut to the chase: better inventory management means more money in your pocket. That’s because using inventory management techniques to increase your ROI means you always have an eye on what is going on with your inventory performance. You end up stuck with less dead stock and you can lean into what products are resonating with your customers, so you purchase more inventory that you know will return a profit.

Inventory management also helps maximize your profits by giving you the information you need to manage your expenses. Knowing your sell-through rate means you can cut down on purchasing costs, for example.

The economic order quantity formula

By taking what you learn from tracking your inventory and applying it to the economic order quantity (EOQ) formula, you can determine exactly how large an order should be to minimize storage and ordering costs.

Q=√[(2DS)/H]

- Q stands for quantity. This is your EOQ-optimized order size

- D is the annual demand for the product you’re measuring. You can check this data by running a report in your point of sale system

- H is your yearly holding costs per unit√

You might not evaluate your optimal EOQ for every single order, but having the data you need to calculate it on hand is important for doing spot checks on your expenses.

Avoid excess stock

Dead and slow-moving stock are both a drain on your resources.

Dead stock doesn’t bring in a profit, which means you can’t replace it. It just stuffs your shelves and storage full of what your customers don’t want.

Slow-moving stock still brings in a profit, but slowly. You can replace it with new stock because it’s still bringing in cash flow, but it’s more akin to a trickle than a steady stream, and it’s in danger of becoming dead stock if customers stop resonating with it altogether.

With an optimized inventory management system, you can catch slow-moving stock before it becomes dead stock. That means you can switch promotional strategies to move that stock before it becomes a problem for your business.

Just-in-time stock management

Just-in-time (JIT) stock management is a method by which businesses time their orders so they always have just enough stock on hand to meet demand without excess or empty shelves.

You need a robust inventory management system to make a JIT method work. Without access to integrated tools and data, you could easily end up ordering too much or too little, defeating the purpose.

How does just in time inventory management improve business?

Avoiding excess stock helps your finances in two ways—you’re not tying up your cash flow in unsold stock, and you can cut down on inventory storage costs. When a significant portion of businesses are all using the method, JIT management can also have a positive environmental impact by reducing waste, as the manufacturing demand can shift at least in part to only filling what’s needed.

However, JIT inventory management can prove a liability during unexpected events. If you suddenly experience a slowdown in deliveries due to shut-downs, JIT stock management can leave you with bare shelves. If you decide to work with JIT stock management, research local suppliers you can switch to, either in a pinch or permanently.

Save time

An ideal inventory management system makes use of technology. No more pen and paper guesswork. That means you save time on your stock management tasks.

Saving time on your regular inventory management tasks means you’ve got room to launch an eCom store. And with an integrated system, you won’t even add a lot of extra inventory management work to your plate.

What are some inventory management techniques retailers should know?

Inventory management is more than just setting your categories and letting things run. There are a number of tools in your toolbox to keep things as efficient as possible.

Inventory valuation

Inventory management is also inventory costing. Knowing how much your inventory is costing you is crucial to making the right purchasing decisions. Attentive inventory management doesn’t leave this unchecked.

Here are a few inventory costing methods you can consider using.

The retail method

The retail method was designed for retailers, exactly as you’d expect. It’s the least accurate individual costing method you’re likely to use, but has value in measuring your cost to retail price ratio. It provides an approximation of your ending inventory balance by comparing the cost and price of your stock.

Because the retail method assumes all of your inventory has a consistent markup, it’s easy to calculate. You just take the total value of what you have for sale and subtract the markup: that’s the approximate cost of your inventory.

You can probably see the downsides to this method, though. If you have products with different markups (and you most certainly do) you won’t get an accurate picture of your inventory’s cost.

Weighted average method

The weighted average method is useful when the prices of the products you buy don’t change often or that much. To calculate it, you use a pool of costs for all units of a particular product. When you make a purchase, it’s added to the pool of cost and then divided by all units you have on hand.

- Let’s say, for example, you bought two batches of a product in a given period. One batch cost $50.00 per unit, and the other cost $53.00

- You purchase 10 of the product in each batch, so in total, you spent $1030.00 on this product’s inventory levels

- In the weighted average method, you’d divide the total cost by the number of units, so you’d have purchased 20 units worth, on average, $51.50

- If you sold three units, regardless of which batch they came from, you’d assume you sold three units that cost you $51.50 each to acquire

This method’s simplicity is both its greatest strength and weakness. It makes costing easy to track, because you don’t need to pay attention to which batch a unit was sold from.

But it can be less accurate than other more specific costing methods, such as FIFO and LIFO, because of the assumptions you make using it while blending your costs together.

FIFO and LIFO

FIFO stands for first in, first out. If you have a batch of sweaters, and you sell one, FIFO assumes you sold the oldest sweater from that batch you had in stock.

- Let’s say you bought two batches of product in a given period. Again, one batch cost $50.00 per unit, and the other cost $53.00. You bought 10 units in each batch, so you spent $1030.00

- You sell 11 units. In FIFO, you assume you sold these units from the older batch first, the one that cost you $50.00 per unit

- 10 of the units sold cost you $50.00 each. One cost you $53.00. In total, you sold inventory that cost you $553.00 to acquire

LIFO, on the other hand, stands for last in, first out. It’s the opposite of FIFO—for costing purposes, it assumes that the last stock you purchased is the first you’ll sell. LIFO is rarely used in retail as it doesn’t present as accurate valuations as FIFO for most retailers. In fact, the LIFO method is banned in most of the world under the International Financial Reporting Standards.

What are the advantages of FIFO?

For most retailers, FIFO offers the most accurate representation of your inventory. While you might not be selling the oldest item in a batch every single sale, you are likely to be moving older inventory before newer inventory.

Regular reconciliation

Regular inventory reconciliation means you’re always on top of what’s going on with your stock. You can catch shrinkage before it gets out of hand, giving you the chance to better pinpoint the cause before it gets out of hand.

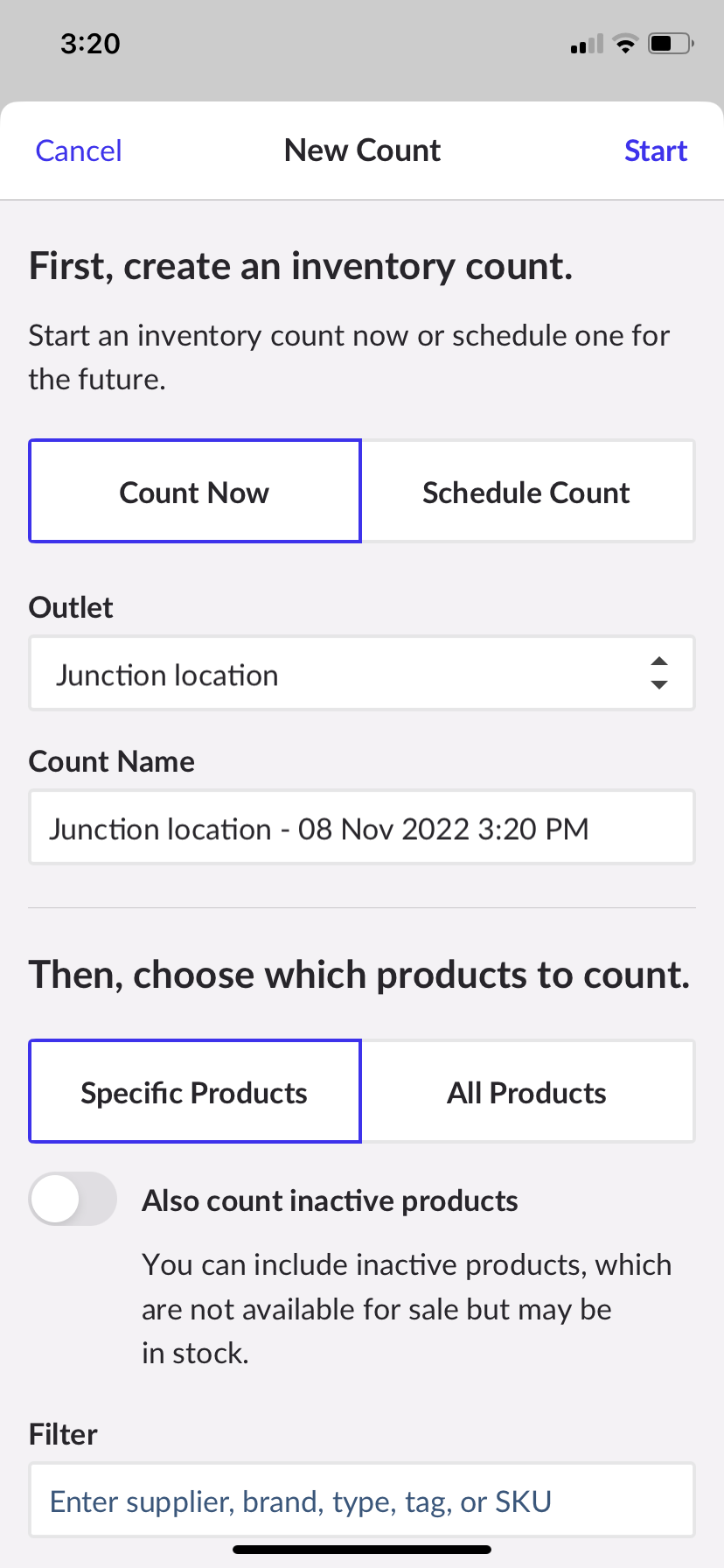

Physical inventory counts

A full physical inventory count means counting every single unit you have on hand. While this gives you the most accurate possible picture of your inventory levels, full counts take a prohibitive amount of time to complete to do that often.

You should perform a full count at least once a year. It’s best to do them when your SKU levels are lowest, typically during the last weekend in January or the end of July.

The main problem with physical inventory counts is how long they take. That means you need to close the store or keep employees after hours, and long, boring counts can lead to errors as people (understandably) start to drift off. To speed up how long full counts take, have multiple employees counting at once using an app like Lightspeed Scanner, which automatically updates quantities in your POS to reduce errors.

Cycle counts

You can bridge the gap between your full inventory counts by cycle counting, wherein you count a smaller amount of inventory more frequently. That way, you still have an eye on your inventory levels without needing to go through your entire stock, something that’d be prohibitively time consuming to do often.

To effectively cycle count, pick a section or two of your inventory to focus on. A bookstore, for example, might decide to count all of their children’s books for a count, but leave the non-fiction books for a different cycle count.

Spot checking

When you spot check, you count the same portion of your inventory for multiple weeks in a row. This helps you find patterns—are any inventory levels experiencing more or less movement than you’d expect? Is there any unexplained shrinkage in a particular kind of product?

You might want to consider doing regular spot checks on your high-risk inventory, such as low-cost accessories that aren’t locked behind a case.

ABC analysis

ABC inventory classification—the ABC stands for activity based costing—is based on the idea that 80% of your revenue will come from the top 20% of your products.

If you were using ABC analysis, you’d sort your inventory into three buckets:

- Group A: the 20% of SKUs that generate 80% of revenue

- Group B: the 30% of SKUs that generate 15% of revenue

- Group C: the 50% of SKUs that generate 5% of revenue

These three categories shouldn’t be customer-facing—they’re for your backend management purposes.

How is ABC analysis useful in inventory management?

ABC inventory classification can help you take more efficient inventory counts.

If you’re employing cycle counting to keep an eye on your inventory, you can use your ABC categories to ensure you’re monitoring the inventory levels of your top performers closely. While your B and C inventory is still generating revenue, they’re not your superstars. These products will need to be counted less often, though they’ll still need counting.

When selecting the products for your inventory counts, you’ll want to focus on frequently counting your group A inventory, and semi-frequently counting your B and C inventory.

Tips for an optimized POS inventory system setup

As a retailer, inventory management is the core of your business. Your POS’ inventory system should be set up in such a way that you can get information from it, not just move products. It should work for you and make your life easier instead of being an extra complication in running your business.

Here are some inventory management best practices you can follow.

Create an optimal hierarchy for your categories

Your categories should follow a consistent internal logic that doesn’t change much over time so you can get the most actionable data possible. This means you shouldn’t be overly specific with your categories—if they’ll only work for very specific products, they’re not the optimal hierarchy.

For example, let’s take an apparel retailer who sells sweaters, both turtleneck and v-neck, from three different brands.

- Your top-level category should be sweaters

- Your sub-categories should be turtleneck and v-neck

- You do not need to make brands a category. Your POS software should track the brands for you

As a rule of thumb, never put more than 10 sub-categories under a single top-level category.

Keep your top-level categories consistent. If one category is sweaters, another could be t-shirts or skirts.

Having an optimal hierarchy for your categories means you can better compare patterns in your sales data going forward, so spend the time to set up a system you could use for years.

Count your inventory

We’ve mentioned the importance of counting inventory a few times in this guide—and that’s because we can’t emphasize it enough. Do cycle counts consistently and often. Keep an eye on your shrinkage.

Set reorder points for all your inventory

A POS like Lightspeed will store reorder points so you only need to run a report to see what products are below their desired inventory level.

Setting your reorder points means you need to spend less time trying to manually monitor what needs to be reordered for every purchase period.

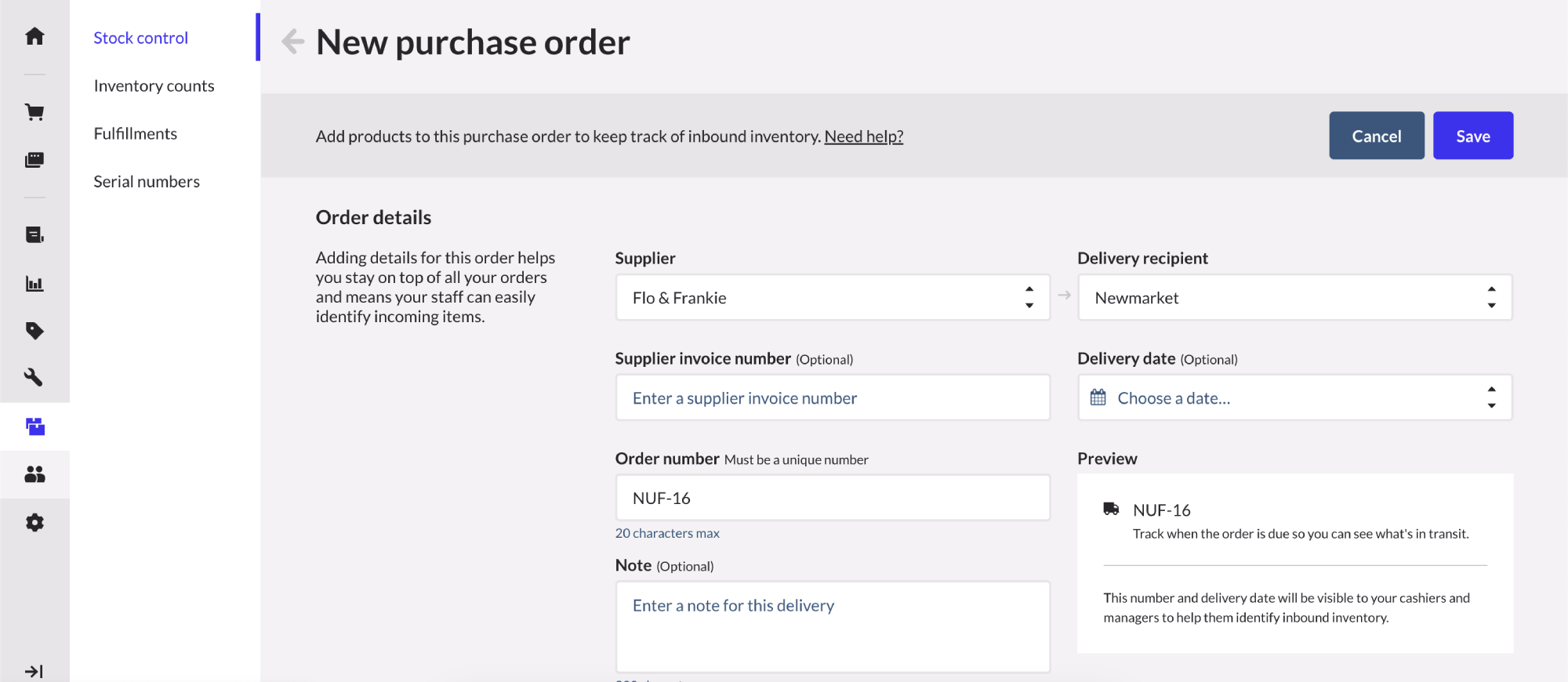

Manage your purchasing from your POS system

When you use inventory management software to manage purchase orders instead of relying on pen and paper or spreadsheets, you’re less likely to make human entry errors, and you save valuable time.

Built-in purchase ordering means your inventory data is easily accessible, which means when it comes time to order you can track important information at a glance, such as:

- Current inventory levels

- Cost per unit

- Open orders and inventory on order

- Inventory in transit to your store

A platform like Lightspeed can go even further by dynamically recommending what products you need to reorder based on reorder points and historical sales volume.

In other words, it can do the forecasting for you.

Inventory management examples

Not all verticals have the same needs. Here are some examples of how different kinds of retail stores might start thinking about their most pressing inventory management needs.

Inventory management for a golf pro shop

Golf pro shop inventory management means keeping an eye on what is, ultimately, ultra-specialized sporting goods store stock.

A pro shop owner might prioritize classifying their inventory with the ABC method. Pro shop customers rarely visit the shop for the shop’s sake alone—they’re around because they’re here to play golf on the course. The pro shop needs to have their top performers on hand at all times, because if they’re sold out of something, it’s much easier for the customer to stop at a different store on their way home than to come back to the course solely to shop.

Once the inventory is classified into groups, the pro shop owner will know to keep a close eye on the reorder points of their A group inventory to prevent stockouts.

Inventory management for a fashion retailer

Stockouts are bad for any kind of retail—but a fashion retailer might approach the problem differently than a pro shop. They could use fashion retail inventory management software to monitor their turns and sell-through so they know how often to make purchases to avoid empty shelves.

Speed is also important in fashion inventory management. The quicker you can get new pieces onto the sales floor, the more you differentiate yourself from your competitors. Fashion giant Zara, for example, uses just-in-time stock management to get new pieces out fast without gambling on excess inventory.

Putting it into practice: buying inventory

So what happens once you’ve got an optimized inventory management setup?

Well, for one, buying inventory is simpler and more streamlined. You’ll have clean, actionable data on hand to make more informed decisions.

Step 1: plan

With an optimized inventory management system, inventory forecasting is easier.

You’ll be able to check what categories and products are performing well—and which aren’t—at a glance.

Take Art for the People, an art gallery powered by Lightspeed in Austin, Texas. Art for the People showcases 100+ artists at any given time, which means they have a complex inventory that requires careful planning.

Thankfully, they have an automated inventory management system on hand, letting them know what commission details they need to watch out for and how different artists and categories of art–and more–are performing. “We can also see if there’s a certain color, fabric or style that sells better and adjust things accordingly,” says Hallie Rae Ward, Art Business Director for Art for the People.

Like with Art for the People, setting up and maintaining your inventory through technology means having a better picture of your inventory sell-through rate. Your sell-through rate helps you predict demand; measuring it means you can build an effective ordering plan.

- A high sell-through rate means your inventory is selling quickly, so you should keep an eye on products with a high rate when it comes time to put in your next order

- Products with a low sell-through rate, however, need new promotional plans, be that through a focus on upselling, discounts, product bundles or otherwise

With inventory performance data on hand, you can set a budget that makes sense. You can more accurately predict demand, so you have a better picture of the ROI of your inventory.

Step 2: buy

Once you’ve planned your budget and taken a look at what inventory is performing well, it’s time to purchase stock.

Look to your point of sale system for help. A POS like Lightspeed has built-in purchase orders so you can manage this step from the same place you manage your inventory. When your stock arrives, you just need to scan it to add it to your management system.

Be sure you create any new categories you might need for your stock under the same optimal hierarchy that you established earlier!

Step 3: manage

Now that you’ve planned, purchased and received your inventory, it’s time to manage it.

Here’s how:

- Set time once a week to check your inventory performance and sell-through rate. Using retail analytics software will help you out here

- Make adjustments to your selling strategy as needed if your sell-through rate isn’t where you want it to be

- Adjust your reorder points as needed based on how quickly or slowly your inventory is selling

- Perform regular cycle counts and spot checks on your inventory to monitor levels and shrinkage

Ideally, you don’t need to be in the store to make quick adjustments. Imagine Exhibitions, a traveling exhibit company whose gift shops are powered by Lightspeed, has managing their inventory from anywhere down to a science. “If we notice a trend or something happens the day before and we’re like, ‘what happened on that?’ We can find out quickly with the system, ” says Michael Slagle, Vice President of Retail Operations at Imagine Exhibitions.

He adds, “We can get that data fast without having to go into a broader, bigger analysis. That’s one of the things that we all like about Lightspeed. That, in my opinion, is better than any of the other POS that we’re using right now. I can go on my phone and get what I need to do. I can be in an airport or something and I can just get onto my phone and see things immediately. And that’s pretty cool.”

What is the future of inventory management?

Inventory management technology looks set to evolve to be more automated and more connected.

Sales associates selling stock and managers ordering inventory will be able to do their jobs more efficiently thanks to wider adoption of tools and technologies like RFID, IOT and automation.

RFID and the Internet of Things for inventory management

RFID, or Radio Frequency Identification, is a way of locating objects (or people or animals) through radio waves. BLE, or Bluetooth Low Energy, works similarly to RFID, but is powered by a low-energy form of Bluetooth. BLE is also called active RFID, because RFID doesn’t use as much energy.

These sorts of technologies power the Internet of Things (IOT), where devices can communicate with each other through networks (either local or connected to the wider internet).

So what do these concepts have to do with the future of inventory management?

RFID and BLE already have their place in warehouses for retailers around the world. They help speed up packing and shipping by helping employees find products quicker. Some retailers are even experimenting with robotics and fully automated warehouses using RFID and similar technology.

In the near future, expect to see:

- Wider adoption of RFID technology in warehouses, even for smaller businesses

- The use of RFID to manage stock in stores, free up space on the sales floor for more experiential retail without sacrificing time at checkout

Automation for inventory forecasting

Many businesses already rely on some form of automation, but expect automated forecasting based on bespoke data to become more commonplace very quickly.

Demand forecasting based on seasonal fluctuations and average vendor lead times helps retailers strike a balance between lean shelves and too much stock. Expect more and more businesses to automate this forecasting to gain an edge without sacrificing time that could be spent elsewhere.

Planning for the future: creating a business continuity plan

Robust inventory management means you’re less likely to be surprised—you have a better handle on your expenses and costs, can keep an eye on your shrinkage and optimize the inventory you have on hand. You know what sells and what doesn’t, so you’re always prepared to serve your customers.

Carry that preparation forward by using what you’ve learned to start your business continuity plan. While you can’t account for everything in your forecasting, you can get yourself ready for the unexpected.

If you’re interested in learning how Lightspeed can help you manage your inventory better, let’s talk.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.