For restaurants, cost of goods sold (COGS) is one of the most important things to measure. Put simply, it’s how much it costs you to produce a menu item.

COGS is important because it’s tied directly to your profit margins, revenue and inventory management. Restaurants who don’t have a firm grasp of their COGS and monitor it regularly put their business in financial risk.

But the good news is that you have control over your COGS. All it takes is a little number-crunching.

In this post, you’ll learn the following:

- What cost of goods sold is

- How to calculate cost of goods sold

- Accessible ways to lower cost of goods sold

Let’s get started!

Build customizable digital floor plans and menus, track sales and inventory and more with Lightspeed’s complete restaurant management platform.Your POS system is your restaurant's heartbeat

What is cost of goods sold?

For restaurants, cost of goods sold is the total cost of all the ingredients used to make menu items, right down to the garnishes and condiments.

As a general rule, roughly one-third of a restaurant’s gross revenue goes towards paying for COGS. Your COGS, along with other restaurant expenses like labor, utility bills and other overhead expenses, is subtracted from your gross revenue to determine your net profit.

Since the cost of produce fluctuates from one season to another, so will your COGS. Your COGS for the same item is likely to fluctuate from week-to-week, month-to-month and year-to-year, that’s why it’s important to routinely monitor it and assure that the price you charge for that menu item leaves you with enough profit, or whether you need to increase it’s menu price to compensate for fluctuations in COGS.

How to calculate cost of goods sold for restaurants

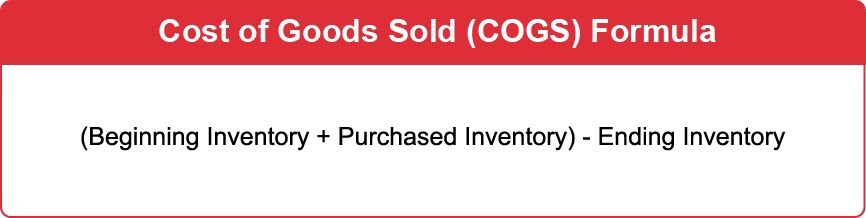

To calculate COGS, you need the following three values for a given time period:

- Beginning inventory: This is the monetary value of the inventory you have leftover from the previous period (day, week, month or year).

- Purchased inventory: This is the monetary value of the inventory purchases you make for the upcoming time period.

- Ending inventory: Once you get to the end of your time period, you calculate the monetary value of the inventory you have leftover.

Once you have those three values, you can calculate COGS.

Cost of goods sold formula

To find your COGS for a given time period, add the value of your beginning inventory and purchased inventory and subtract the value of your ending inventory from the result.

Understanding cost of goods sold

Let’s say Johnny’s Burger Bar wants to find their COGS for the month of February. They had $3,000 of leftover inventory from January (this is beginning inventory since they’re starting the new time period with it). That leftover inventory included ground beef, drinks, buns, garnishes and vegetables (any ingredients needed to make the food they serve).

During the month of February, they had to restock and buy $2,000 worth of food inventory. They ended February with $500 worth of food inventory.

COGS = ($3,000 + $2,000) – $5,00

COGS = ($5,000) – $500

COGS = $4,500

Johnny’s Burger Bar’s COGS for the month of February—the amount of money they spent on the food and drink that they served during that month—was $4,500.

What this number means for your restaurant

So you’ve calculated your COGS, now what can you do with this number? Some say the ideal cost of goods sold percentage is around 30-40%. However, for restaurants, there are a lot of factors that go into this including how labor-intensive your items are, how much you are able to charge for them, your location and rent, and more.

It is possible for items to have a higher COGS percentage but bank more money, so it’s important to also look at the dollar amount each item is bringing in. Selling a dish that cost you $5 to make that you charge $15 for (33.3% COGS) will bring in $10, but a higher end dish that costs you $25 in inventory but you can charge $50 for (50% COGS) will still bring you more money at the end of the day.

6 ways to lower cost of goods sold

The lower your cost of goods sold, the higher your restaurant’s profit margins will be. No matter what type of establishment you operate, it’s in your best interest to find ways to lower your COGS without sacrificing food quality and jeopardizing customer satisfaction.

Here are six actionable ways to lower your cost of goods sold:

- Keep a close eye on inventory

- Buy in bulk whenever possible

- Compare vendors

- Reduce food waste

- Consider redesigning your menu

- Purchase less expensive products

1. Keep a close eye menu item sell-through

You don’t know how much inventory and food supplies you need unless you closely monitor each menu item’s sell-through. Assure that you’re only purchasing the food supplies that you know you can sell over a given time period.

Look at sales reports and calculate how much food supplies you need to meet demand. Only purchase what you know you’re going to sell to avoid wasting money on COGS that will ultimately spoil.

Key takeaways:

- Buy enough food supplies to meet customer demand for each menu item.

- Use the sales reports your point of sale system generates to see how much of each menu item you sell, then calculate how much of each ingredient you need per menu item to meet demand.

2. Buy in bulk whenever possible

Some suppliers offer special pricing to restaurants who purchase in bulk. When purchasing non-perishables (food with a long shelf life) or food that your restaurant sells quickly (food with a fast turnover), purchasing in bulk is an effective way to get discounted pricing and lower your COGS.

For example, let’s say Johnny’s Burger Bar works with a supplier who gives him a 75 cent discount per pound of ground beef he purchases, and each of his burgers contains a quarter pound of beef. Per month, Johnny’s Burger Bar usually goes through 1,000 pounds of ground beef (4,000 burger patties). By purchasing in bulk, Johnny’s Burger Bar lowers the COGS per burger by 18 cents and saves $750 per month.

One common concern for purchasing in bulk is that it may compromise the food’s freshness, as well as storage space. Not every restaurant has enough space to store 1,000 pounds of ground beef or a fast enough turnover to avoid waste or spoilage. Assure that you only purchase an amount that you know you can sell prior to it spoiling.

Key takeaways:

- Suppliers may offer special pricing to restaurants who purchase in bulk.

- Only purchase for an amount that you know you can sell prior to it spoiling.

- Be mindful of storage space. Only purchase an amount that you can reasonably store.

3. Compare vendors

When working with suppliers, it’s important to see how one’s quality and pricing stacks up against another. It’s in your best interest to compare the pricing of multiple vendors. If one is cheaper than another and has similar food quality, consider seeing whether or not the other supplier is willing to offer more competitive pricing.

For example, let’s say Johnny’s Burger Bar finds another similar supplier for ground beef, whose offering an 85 cent discount per pound of ground beef he purchases. That lowers his burger’s COGS by 21 cents and saves him $850 per month—$100 more than his current supplier.

Maintaining healthy relationships with suppliers is important for any business, not just restaurants. Before starting a price war, consider how much you value your existing suppliers. Your goal isn’t to extort them, just to have an open conversation about pricing.

Key takeaways:

- Compare the pricing of suppliers who offer the same products to assure you’re getting the best price possible.

- During supplier negotiations, always factor in their business needs as well. You want to maintain a healthy business relationship that’s financially beneficial for all parties involved.

4. Reduce food waste

Regardless of how accurately you’re inventory taking is, food waste is a big contributor to a high COGS. But the good news is that food waste is preventable.

For instance, if you have food supplies that are going to turn soon, have your chefs find creative ways to use those ingredients. For example, rather than throw away bread that’s at risk of going stale, consider using it in an onion soup. Meat not at optimal freshness? Consider dry-aging or curing it according to the USDA’s processing procedures.

Key takeaways:

- Get your chefs into the habit of finding creative ways to use food supplies that are close to turning.

- Want to really crack down on food waste? There’s emerging restaurant technologies that can help.

5. Consider redesigning your menu

Your menu’s design has a huge impact on what menu items guests order. Anything from which layout you choose to its colors and descriptions will affect which dishes they choose.

Menu engineering is the art of deliberately and strategically designing a menu to encourage guests to purchase high-profit margin menu items. Creating a menu using menu engineering tricks, restaurants can indirectly influence which items customers are naturally drawn to, increasing sales of the menu items that are best for their bottom line.

Key takeaways:

- A restaurant’s menu design indirectly influences which menu items guests’ purchase.

- Consider re-designing your menu using menu engineering strategies that are proven to increase sales.

6. Purchase less expensive products

For all intents and purposes, this should be a restaurant’s last resort. If you start serving customers lesser-quality food while charging prices, customers will notice and it may put your restaurant’s reputation at risk.

One way to spend less on food supplies without compromising food quality is to compare vendors and assure you’re getting the best price possible. Another way to lower costs is to explore working with different suppliers for different products.

For example, let’s say Johnny’s Burger Bar wants to introduce chicken burgers to their menu. While their current meat vendor’s pricing for ground beef is great, it’s less desirable for chicken. For 500 pounds of chicken, it would cost Johnny’s Burger Bar $1.00 per pound for a total of $500. Another supplier who specializes in poultry, however, is offering $500 pounds of chicken at 50 cents per pound, for a total of $250. By working with two suppliers, one for beef and one for poultry, Johnny’s Burger Bar is saving an additional $250 per month on COGS.

Key takeaways:

- Don’t sacrifice your customer’s dining experience in the pursuit of lowering COGS. Customers will notice and it may result in a spike in negative online reviews.

- Always factor in food quality. Naturally, better quality products will cost more. If you purchase high-quality ingredients, make sure your menu pricing leaves you with enough gross profit.

COGS: a delicate balancing act

No matter what type of restaurant you run, achieving the optimal balance between food quality and COGS is vital for your restaurant’s long-term profitability.

The good news is that optimizing cost of goods sold isn’t a matter of chance, it’s well within your control. Whether you work with cheaper suppliers, buy in bulk to obtain beneficial pricing or even increase menu prices to earn more gross profits on each dish you sell, there are plenty of ways to optimize your COGS and increase profits.

With some number-crunching, careful planning and paying attention to the details, you can set your restaurant up for prosperity.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.